Serving all of Long Island & the Hamptons Daily!

What Types of Metal Supplies Do You Need for Your Project?

When choosing the appropriate metal supplies for your project, your key consideration should be the actual application requirements of the project and the environmental issues it's likely to face. Other considerations include weldability, tensile strength, corrosion resistance, ductility, machinability, cost, and versatility. Let's look at the types of metal supplies you may need for your project.

Hot Rolled Carbon Steel

You have various options when it comes to hot rolled carbon steel. You can choose from high-carbon, low-carbon, and medium-carbon steel. The exact metal supplies that you need will depend on the requirements of your project.

Steel Angle Bar and Steel Plate

A steel angle bar is perfect for all manner of repairs, structural applications, and fabrication. Use steel angles in transportation equipment, industrial maintenance, and agricultural implements. Using the right angles guarantees a project's structural integrity.

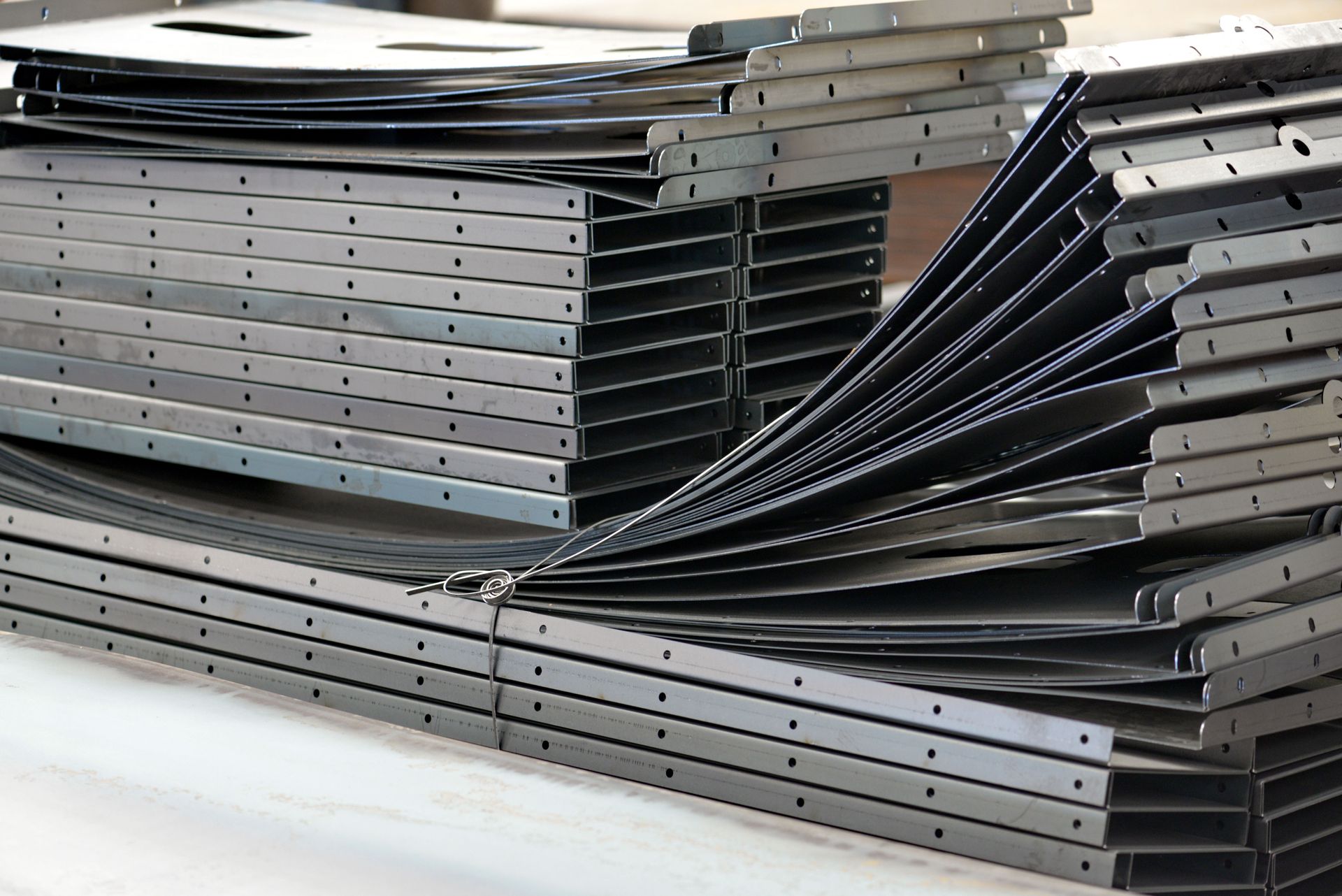

Beams and Channels

These come in various sizes. The rationale for the shape is to provide excellent structural support, which makes them perfect for braces and frames. For example, beams and channels are great for roofing projects.

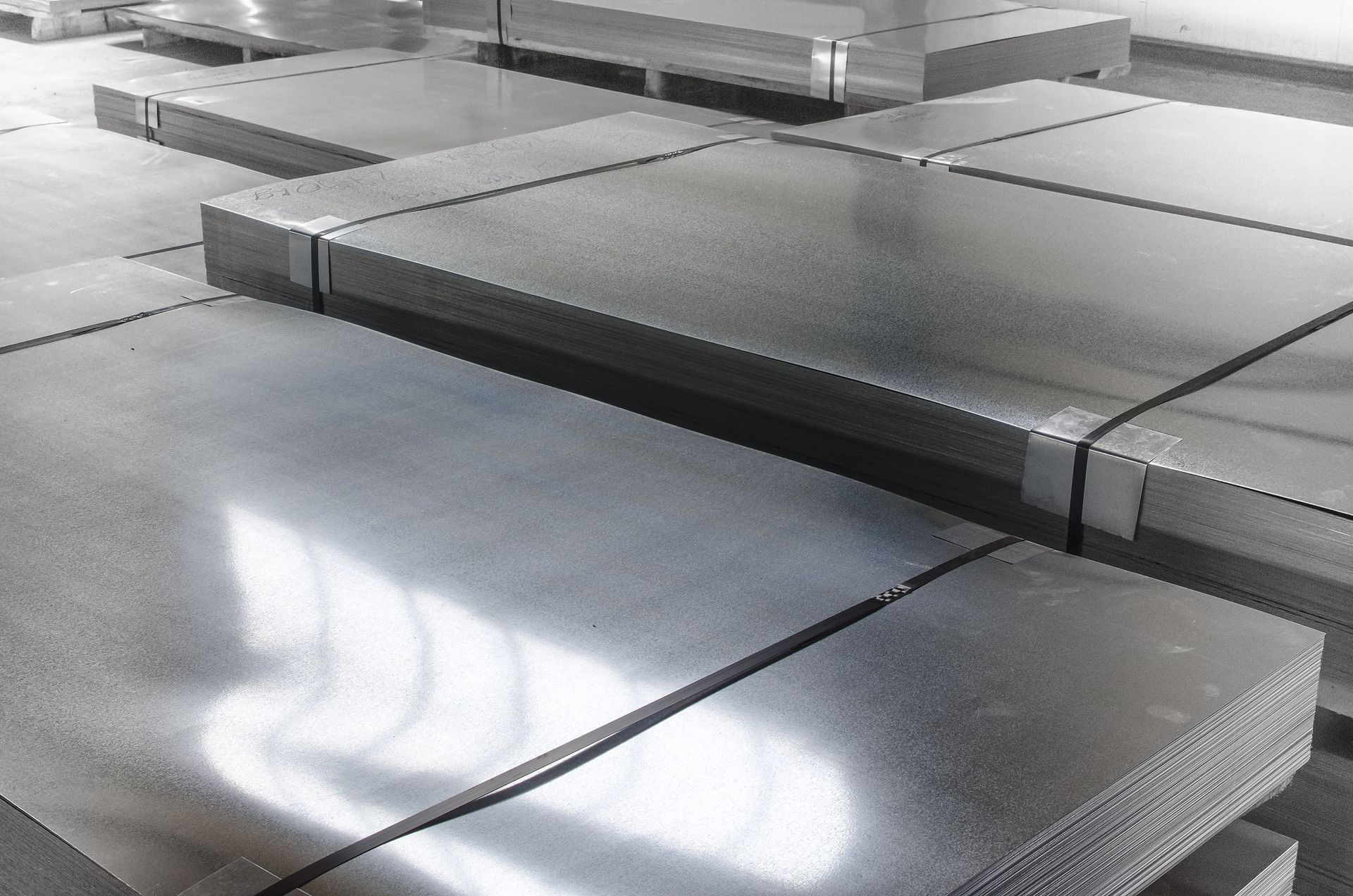

Plates

Carbon steel plates are produced from ingots manufactured through basic oxygen, an electric furnace, or an open hearth process. Choose from sheared-flame cut, regular quality, and hot rolled carbon steel plates. These plates can also be cut down to the size you need.

Sheets

According to Market Research Future, the building and construction sector comprises 52% of all sheet metal in the marketplace, mainly from materials used in HVAC systems, gutters, and roofs. For your project, consider pickled, hot rolled, or oiled sheets. These are easy to fabricate, have good ductility, and feature a clean, pickled, superior smooth finish.

Cold Finished Bars

Cold finish bars are another material you may need. Polished shafting and screw steel are some of the popular cold-finished bar products. Others are turned and polished (T&P), cold drawn (CD), and ground and polished (TG&P).

Pipe and Tube

The difference between pipes and tubes is often confusing for many people. Pipe products can be used for applications including fluids and gas. Alternatively, a tube is a rectangular, round, oval, or square hollow used in instrumentation systems, mechanical applications, and pressure equipment.

Stainless Steel

This family of iron-based alloys is renowned for heat resistance and corrosion. Steel has a high chromium content, giving it higher corrosion resistance. This makes it very useful in various applications.

Aluminum

Aluminum can be used for many things. It is used to manufacture kitchen utensils, cans, foils, beer kegs, window frames, and airplane parts. It has high thermal conductivity, low density, high corrosion resistance, nontoxicity, and is easy to cast, machine, or form.

Brass

A metal alloy comprising of copper and zinc, brass' unique properties make it very popular. Even after forming, which it does easily, it remains strong. Since bacteria hate it, brass is ideal for doorknobs, bathroom fixtures, and medical applications.

Threaded Rod

Threaded rod is made from stainless steel, carbon, or coated with zinc. It's used to join two items, such as metal or wood, and to connect concrete and other materials. Because of this, threaded rod is a popular metal product used in deck building and building construction.

Among the characteristics of metal supplies are reliability and high performance. The right metal should meet the specifications and requirements of your project. No matter what type of metal supplies your project needs, we have a wide variety to choose from. Go ahead and give us a call at Public Metals Corp. today.

Share On: