Serving all of Long Island & the Hamptons Daily!

3 Key Parts of Materials Manufacturing

Local metal suppliers can produce high-quality goods for all kinds of applications. Of course, having easy access to those materials is always welcome. But have you wondered about how those products are fashioned from raw materials? Let's learn more about that process by discussing three key steps involved in materials manufacturing.

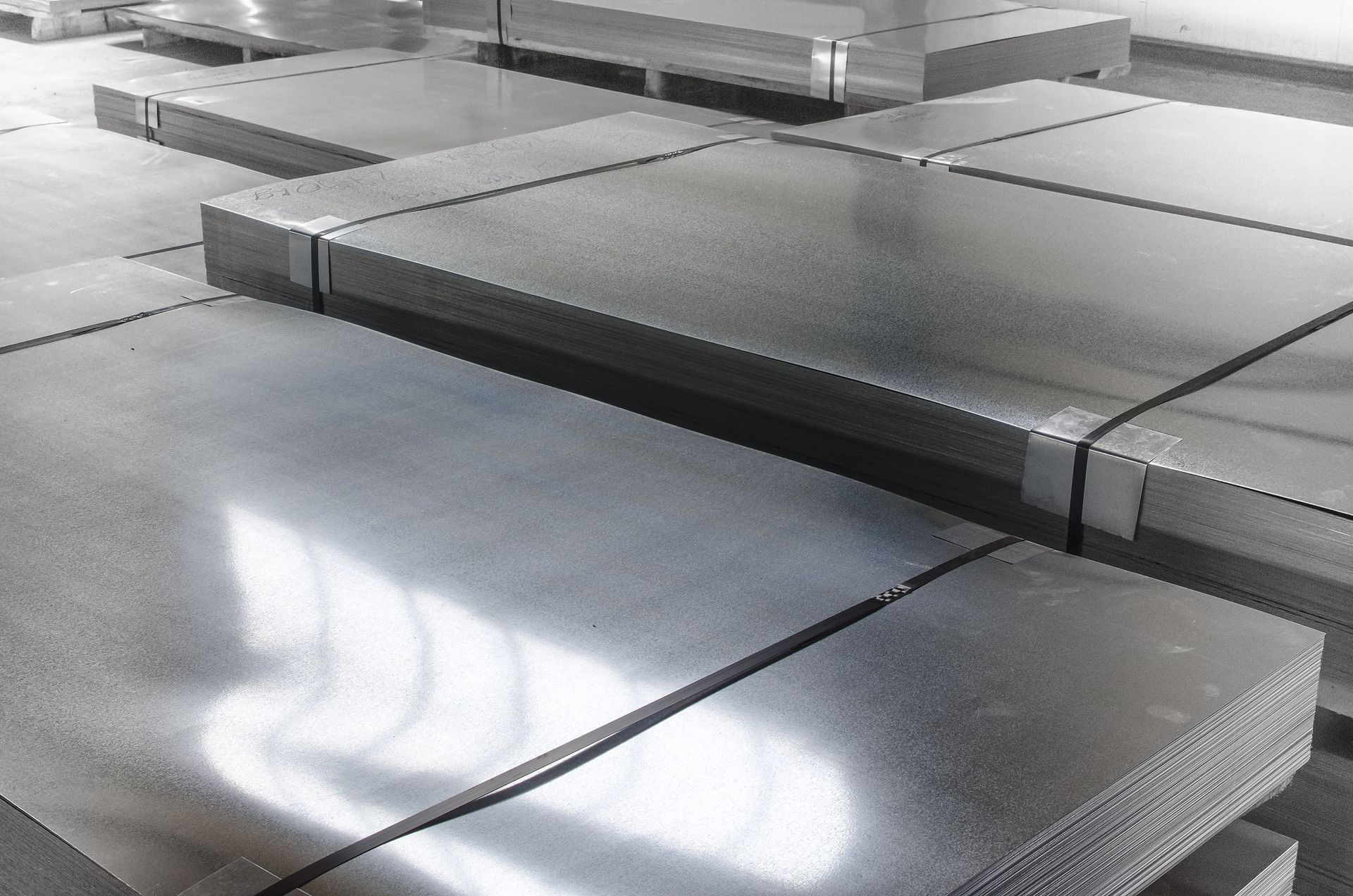

1. Gathering the Finest Raw Materials

The secret to manufacturing high-quality products is starting with top-notch raw materials. However, even the most elaborate manufacturing process cannot cover up for innate material flaws. These raw materials may be mined from mineral deposits or extracted elsewhere. Notably, the manufacturing company doesn't have to be directly involved in the process of securing the raw materials. They can work with reputable suppliers and purchase raw materials from them. Manufacturing businesses can benefit significantly from browsing the marketplace for the best raw materials available. Investing in top-notch goods also allows them to produce materials of impeccable quality that can be sold at high prices.

2. Designing the Materials to Be Produced

Next up, manufacturing companies have to determine how their materials will be designed. You might have assumed that product design is unnecessary for manufacturing companies. They should be able to keep their business strong as long as they can consistently churn out the materials their customers want. Of course, creating those materials requires thoughtful design. Manufacturers must understand which qualities of the material they want to emphasize during the fabrication process. In some cases, they may have to choose between specific qualities because highlighting all of them in the finished product is impossible. Businesses in this industry should also account for how accessible their products are. They need to produce materials suitable for various applications, or else their customers may fail to see the value in their work.

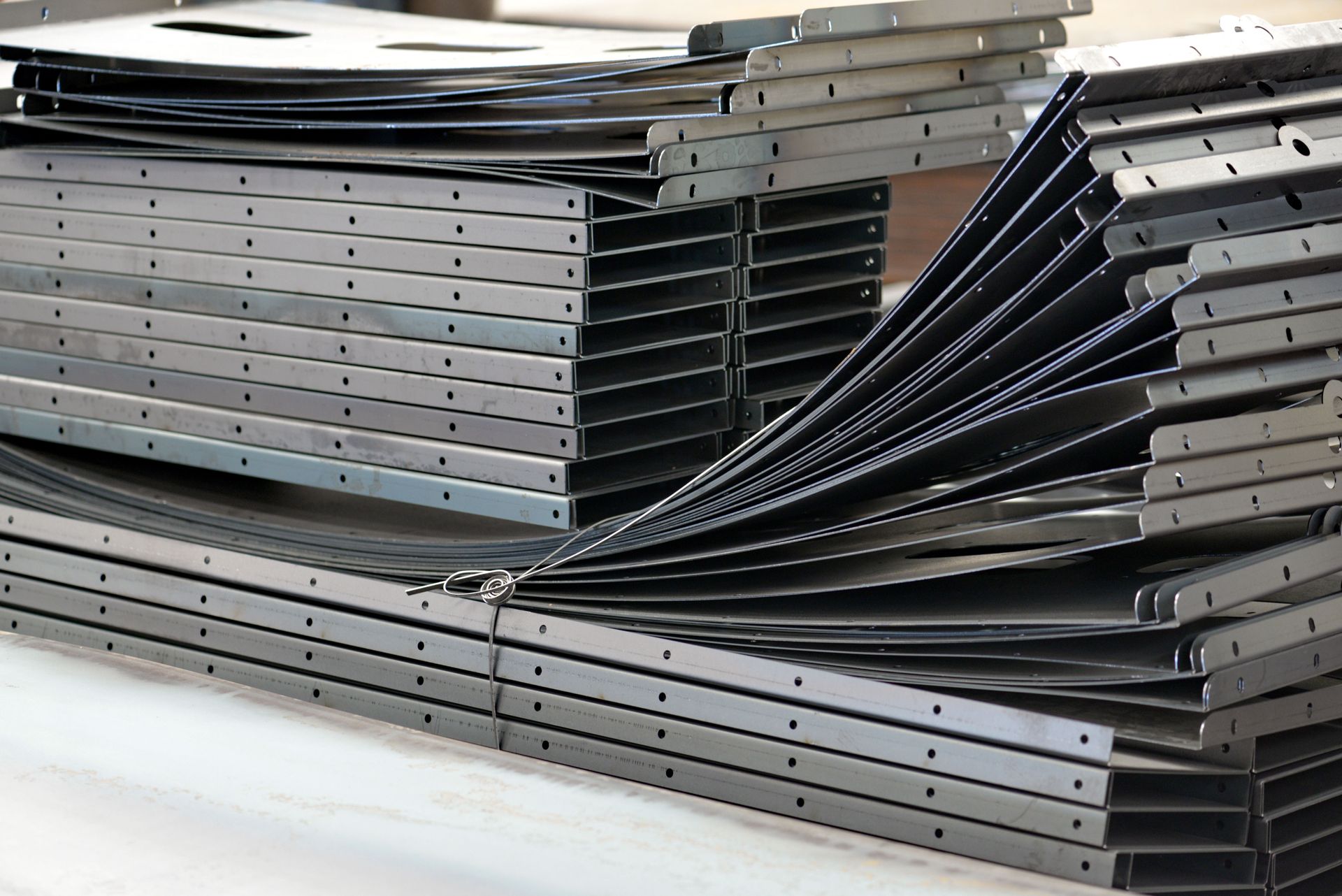

3. Fabricating the Raw Materials

Smelting, molding, and cutting are just some of the processes in fabricating raw materials. The specific chain of methods that a manufacturing business must use will depend on the type of materials they deliver to the market. Manufacturing businesses must build their facilities based on the steps involved in their process. Businesses must also invest in the best tools available. According to the Manufacturing Network, a high-powered plasma cutting machine can produce cuts as deep as 150mm. Local metal suppliers can benefit significantly from having those machines in their facilities.

Even for the most experienced

local metal suppliers, the manufacturing process can become complex. Focusing on the fundamental parts of the manufacturing process will help them produce better materials. Call us today at Public Metals Corp to learn more about manufacturing businesses and their work.

Share On: